Lubricating points

Raziol lubricating points with a precision coaxial spray head incorporating an articulated holder and magnet base for positioning the “spray jet” are suitable for both use with Raziol control units for non-cutting machining such as deep drawing, stamping and bending and cutting machining such as drilling and milling.

The Raziol lubricating points are used in conjunction with Raziol control units for non-cutting and cutting metalworking applications.

A variety of nozzle attachments featuring various diameters are used for different oil volumes and viscosities.

Precision spraying head extensions in different lengths and diameters enable exact lubrication.

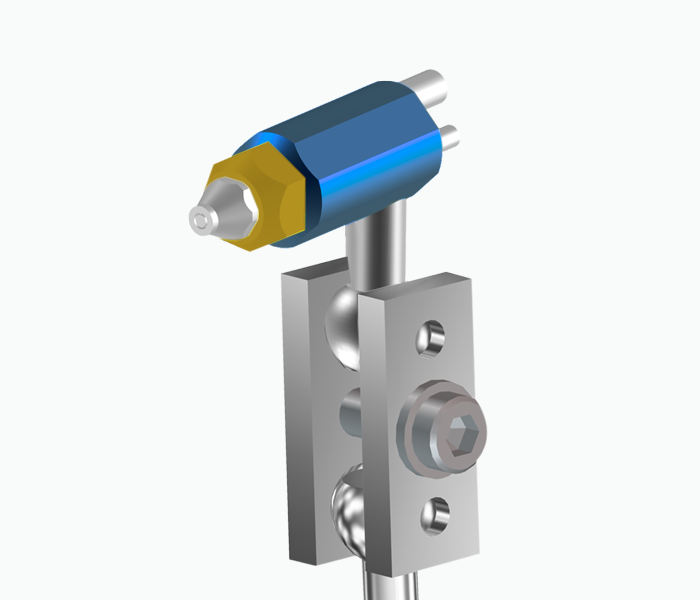

ST LAMA-1000 lubricating point

LAMA-1000 lubricating points consist of a coaxial spray head incorporating a magnet holder and magnet base for positioning the “spray jet”. Use of different nozzle attachments with different diameters enables the application of different oil volumes. The minimum possible application volume for the LAMA-1000 is <0.5 g/m². It is suitable for the application of high-viscosity lubricants.

LAMA-1000 lubricating points consist of a coaxial spray head incorporating a magnet holder and magnet base for positioning the “spray jet”. Use of different nozzle attachments with different diameters enables the application of different oil volumes. The minimum possible application volume for the LAMA-1000 is <0.5 g/m². It is suitable for the application of high-viscosity lubricants.

This system is used in conjunction with Raziol control units for tool lubrication and minimum quantity lubrication during non-cutting operations, e.g. deep drawing, stamping, bending, profiling and thread forming, as well as for machine cutting, such as drilling and milling operations.

"The ST LAMA-1000 HL and HL Streu lubricating points are equipped with a high-performance nozzle (HL) which is particularly suitable for lubrication

tasks where formed parts also need to be lubricated over a long distance and where rapid lubricating sequences are required. 4 different nozzle attachments with different diameters for different oil volumes and viscosities can be employed to change the lubricating pattern.

ST LAMA-1000 variants and characteristics »PDF

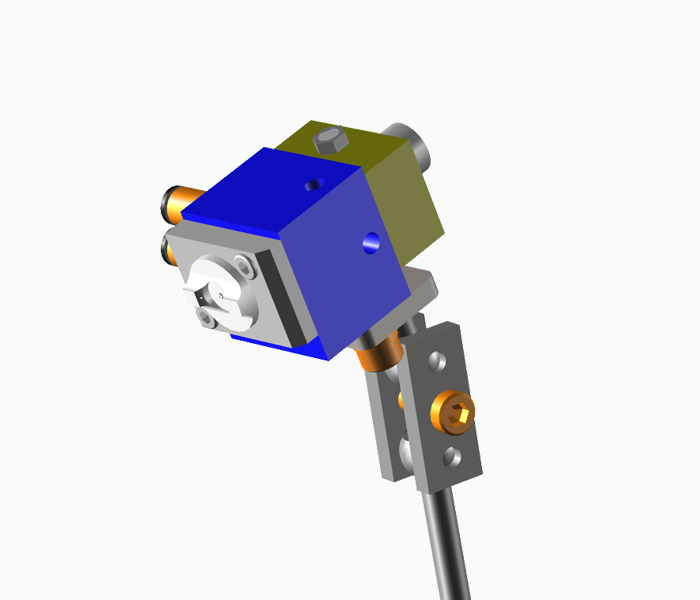

ST LAMA-3000 lubricating point

LAMA-3000 lubricating points consist of a coaxial spray head incorporating an articulated holder and magnet base for positioning the “spray jet”. Use of flexible spray head extensions with different lengths enables accurate lubrication on forming tools and cutting machining tools.

LAMA-3000 lubricating points consist of a coaxial spray head incorporating an articulated holder and magnet base for positioning the “spray jet”. Use of flexible spray head extensions with different lengths enables accurate lubrication on forming tools and cutting machining tools.

Precision spray head extensions are provided with extended lubricant tubes for pronounced bends (length = xxx mmm (+20 mm))

The LAMA-3000/VL must be used with precision spray head extensions (1080720088).

They are used in conjunction with Raziol control units for tool lubrication and minimum quantity lubrication during non-cutting operations, e.g. deep drawing, stamping, bending, profiling and thread forming, as well as for machine cutting, such as drilling and milling operations.

The minimum possible application volume for the LAMA-3000 is <0.5 g/m², it is suitable for the application of low to medium-viscosity lubricants.

ST LAMA-3000 variants and characteristics »PDF

ST LAMA-4000 lubricating point

LAMA-4000 lubricating points consist of a coaxial spray head incorporating an articulated holder and magnet base for positioning the “spray jet”.

Use of different nozzle attachments enables modification of the lubricating pattern. Different nozzle diameters enable lubrication of tools with different oil volumes.

Where wide spray attachments are employed, the ST LAMA-4000 VA (1080045002) is used with the VA nozzle body (part no. 1080045000).

They are used in conjunction with Raziol control units for tool lubrication and minimum quantity lubrication during non-cutting operations, e.g. deep drawing, stamping, bending, profiling and thread forming, as well as for machine cutting, such as drilling and milling operations.

The minimum possible application volume for the LAMA-4000 is <0.5 g/m², it is suitable for the application of low to medium-viscosity lubricants.

ST LAMA-4000 & ST LAMA-4000 VL variants and characteristics »PDF

Schmierstelle ST DUSTY-2000

DUSTY-2000 lubricating points consist of a coaxial spray head incorporating an articulated holder and magnet base for positioning the “spray jet”.

The oil volume and spray air can be adjusted directly on the nozzle head.

Counterclockwise rotation: more lubricant or more spray air

Clockwise rotation: less lubricant or less spray air

The lubricating point can be applied in conjunction with precision spray head extensions of various lengths (50 mm - 800 mm).

The spray head extension tube is flexible and can therefore be accurately positioned on the point to be lubricated. Where the extension is employed,

the ST DUSTY-2000/VL is used with the DUSTY 2000/VL coaxial spray head (part no. 1080720073).

They are used in conjunction with Raziol control units for tool lubrication and minimum quantity lubrication during non-cutting operations, e.g. deep drawing, stamping, bending, profiling and thread forming, as well as for machine cutting, such as drilling and milling operations.

ST DUSTY-2000 & ST DUSTY-2000 VL variants and characteristics »PDF

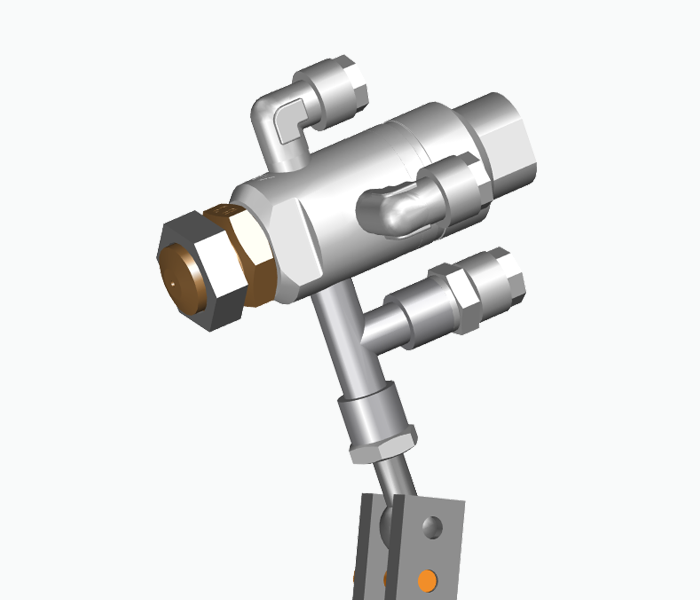

ST CD-100 BS(D) lubricating point

CD-100 lubricating point wide spray air (restrictor)

CD-100 BS(D) lubricating points consist of a coaxial spray head incorporating an articulated holder and magnet base for positioning the “spray jet”.

Spray parameters can be effectively adjusted with excellent reproducibility of the lubricant volume to be applied. The control air actuates the nozzle. Applying spray air to the oil outlet reduces the medium to micro droplets (depending on the configured pressure). Flattening of the otherwise circular nozzle lubricating pattern is realised by the wide spray air. The lubrication width of each nozzle can be influenced by the configured pressure of the wide spray air.

An adapter plate is required to fasten the nozzle to the articulated holder.

They are used in conjunction with Raziol control units for tool lubrication and minimum quantity lubrication during non-cutting operations, e.g. deep drawing, stamping, bending, profiling and thread forming, as well as for machine cutting, such as drilling and milling operations.

ST CD-100 BS(D) variants and characteristics »PDF

ST CD 95 / 105 lubricating point

CD 95 / 105 lubricating points consist of a coaxial spray head with a 90° flat section jet spray angle incorporating an articulated holder and magnet base for positioning the “spray jet”. An adapter plate is required to fasten the nozzle to the articulated holder. Nozzle attachments with nozzle outlets of 0,5 mm, 1,0 mm, 1,5 mm are applicable. Different attachments are available for different lubricating patterns (wide spray attachment, round spray attachment, swirl attachment)

Spray parameters can be effectively adjusted with excellent reproducibility of the lubricant volume to be applied.

This lubricating point is applied in conjunction with Raziol control units for tool lubrication and minimum quantity lubrication during non-cutting machining, such as deep drawing, stamping, bending, profiling and thread forming. Fitted to spraying fixtures, they are also installed in spray chambers.

ST CD-95/105 variants and characteristics »PDF

English (UK)

English (UK)  Français (France)

Français (France)  Deutsch

Deutsch  Español (España)

Español (España)  Polski (PL)

Polski (PL)  简体中文(中国)

简体中文(中国)