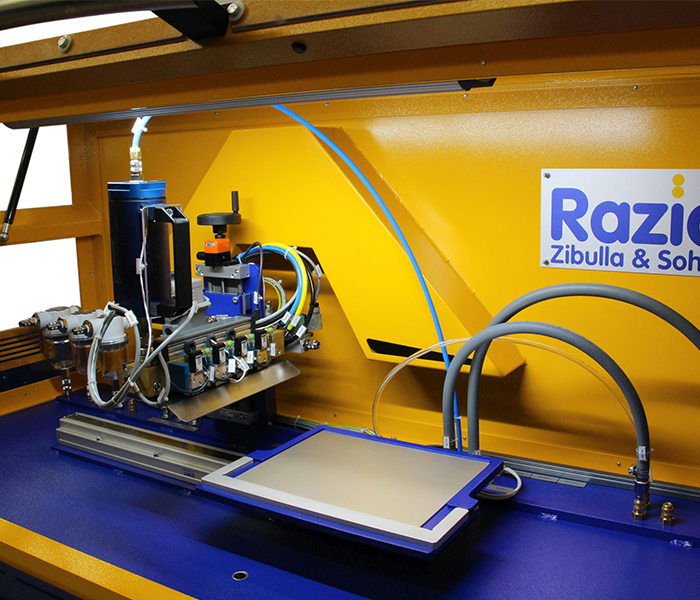

Laboratory lubrication system

The Raziol laboratory lubrication system was developed and constructed by Raziol Zibulla & Sohn GmbH some years ago. Since then, it has become an integral and invaluable tool in the development departments of our most renowned customers, including Daimler, BMW and VW.

The laboratory lubrication system is used for the application of defined, reproduced oil quantities, or hotmelt as required, onto a test body. Application of the lubricant is performed for various testing of compatibility for the follow-up processes, for example adhesive examinations, degreasing tests, checking EPD compatibility, weldability, tribological assessments, etc.

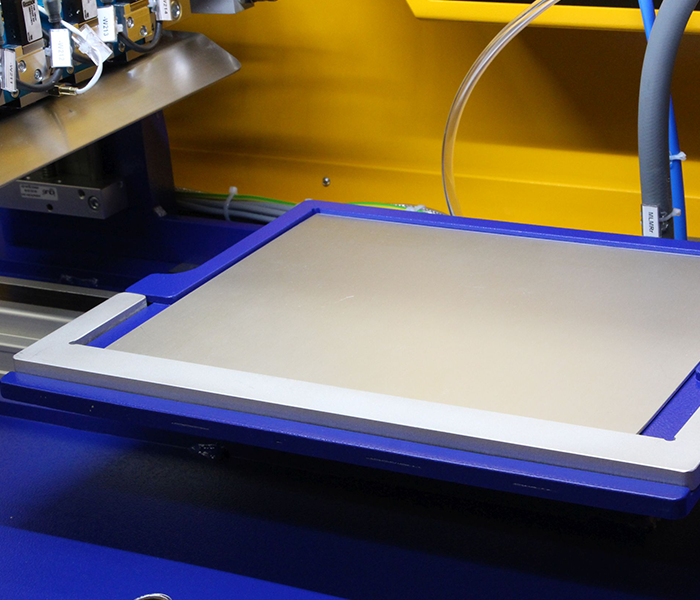

It is designed for the lubrication of test substrates featuring dimensions of up to 297 mm x 210 mm (DIN A4), as well as sheet metal strips of approx. 50 mm x 650 mm. A relatively quick and straightforward change of medium allows the application of diverse lubricants.

Measuring and evaluation software, including hardware customised for the application of oil specific to the respective problem was developed by the Raziol Control Unit Department. This software provides target-oriented data acquisition, video and audio recordings, management of measurement data in a database system, online representation of diagrams, etc. It is extremely easy to use and can store up to 1000 lubricant-specific items of data.

The laboratory lubrication system is configured for connection to an exhaust system.

English (UK)

English (UK)  Français (France)

Français (France)  Deutsch

Deutsch  Español (España)

Español (España)  Polski (PL)

Polski (PL)  简体中文(中国)

简体中文(中国)