Spray lubrication systems

As well as the standard configurations for our spray lubrication systems, Premium SA-P spray system, SlimLine SKT-SL spray chambers, Basic SKT-B spray chambers and folding chambers, our engineers devise expert solutions which are optimally configured to special and individual requirements of the customer.

We supply high-performance spray systems which are optimally equipped for applications in fully automatic production lines: The user-friendly control can be integrated in the visualisation concept of presses, the WinBBE lubrication pattern editor for creating lubrication patterns for different oil volumes and feed speeds enables individual, flexibly controllable and precision lubrication and precision nozzles ensure reproducible application volumes of different lubricants.

Our product range thus comprises spray lubrication systems of any scale, developed and manufactured in accordance with respective customer specifications.

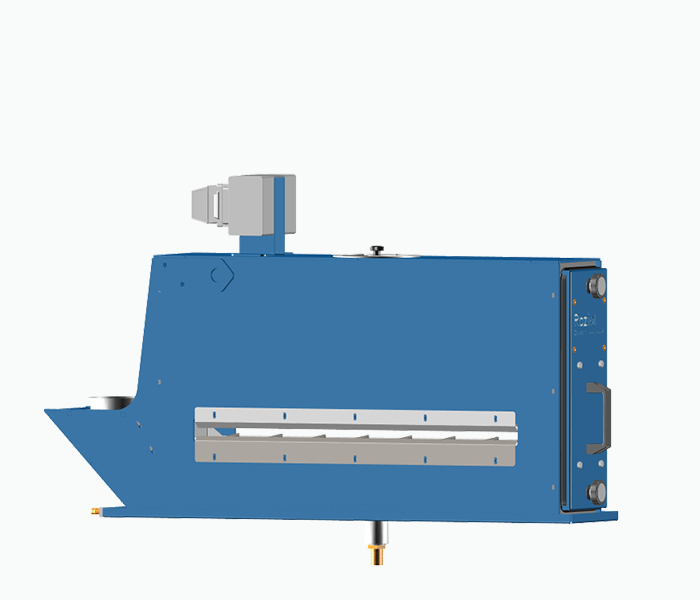

SlimLine SKT-SL spray chamber

Lubrication system without transport unit in the spray chamber for short blanks and minimal installation conditions

SlimLine SKT-SL spray chambers are spray systems for partial or sectoral lubrication of coil material or blanks with a width of up to 4.500 mm. The spray chamber structure is design especially for precision lubrication of blanks without a transport unit inside the chamber. SlimLine spray chambers are highly suitable for integration in fully automatic production lines.

A very high level of reproducible precision is achieved in the application area and quantity, thanks to the BS 25 SRV Mini-15 minimum lubricator nozzles. Different application quantities in and transverse to the material throughfeed direction can be programmed in this respect.

Function/ Equipment

- Lower space requirement in throughfeed direction

- Consists of a spray chamber with BS 25 SRV Mini nozzles in block design and a nozzle pitch of 100 mm

- Fully automatic setting of all necessary system parameters

- User-friendly software structure and function (touch PC with link to higher-level control)

- Beckhoff / Siemens control unit incl. maintenance and diagnostic tools

Slim Line SKT-SL variants and characteristics »PDF

Basic SKT-B spray chamber

Standard spray system for one-sided/double-sided, full-surface or sectoral lubrication of coil material

Basic SKT-B spray chambers are spray systems for one-sided/two-sided, complete surface or sectoral lubrication of coil material for different lubrication widths up to max. 1900 mm. The special feature of this standard Raziol spray chamber system design is the extremely low passline. The spray chamber consists of up to 19 nozzles per spray beam top and bottom and transition zone inside the spray chamber.

The nozzle bars and their holders can be pulled sideways out of the chamber (without tools) for maintenance, calibration and cleaning tasks.

Function / Equipment:

- Consists of a spray chamber with two integrated spraying fixtures with up to 17 nozzles top and bottom per nozzle bar and a transfer zone inside the spray chamber

- Equipment of nozzle bars with BS 25 SRV Mini nozzles with a nozzle pitch of 100 mm

Basic SKT-B spray chamber variants and characteristics »PDF

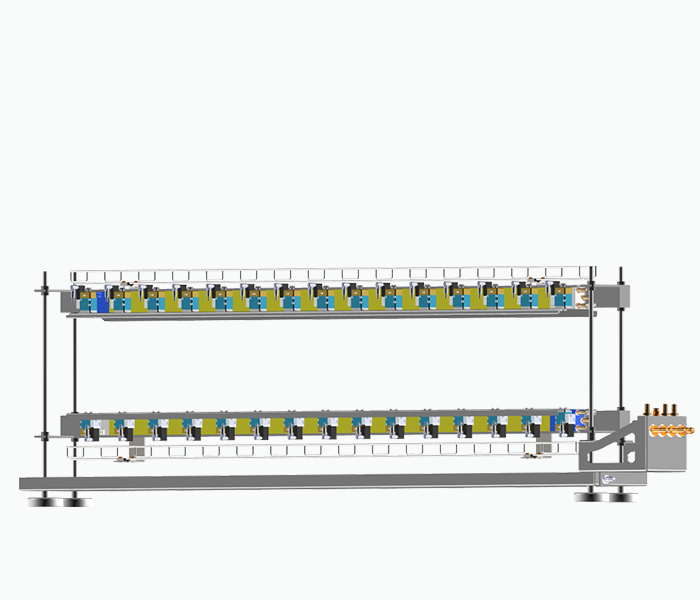

Basic SB spraying fixture

Spraying fixtures for one-sided/double-sided, full-surface or sectoral lubrication of coil material

The Basic SB spraying fixture is suitable for one-sided/two-sided, complete surface or sectoral lubrication of coil material for 8 different lubrication widths, max. 1900 mm.

The special feature of this standard Raziol spraying fixture system design is the simple structure with nozzle bars which can be adjusted in height and varied in width.

Function/Equipment

- Consists of 2 nozzle bars with lateral connections for medium, air and electrical systems and 4 magnet holders for secure fixing

- Equipping of nozzle bars with up to 19 BS 25 SRV Mini-15 nozzles top and bottom with a nozzle pitch of 100 mm

SB spraying fixture variants and characteristics »PDF

SK folding spray chambers

Folding spray chambers for double-sided lubrication of coil material

Our folding spray chambers are suitable for double-sided oiling/lubrication of coil material. The special feature of the folding spray chambers is the tilting mechanism, which allows the upper section of the chamber to be folded out around 110°. Loosening of the cross handle or the safety catch permits easy opening of the chamber. Depending on the respective configuration, complete nozzle bars (compact design configuration) or individual minimum lubricator nozzles can be installed in the upper or lower section of the chamber. The nozzle bars within the chamber may also be folded upwards to facilitate maintenance and servicing tasks. Brush strips on the infeed and outfeed sides of the spray chamber prevent the volatilisation of oil mist. The spray chamber features screws to allow assembly onto a console fitted by the customer.

SK spray chamber variants and characteristics »PDF

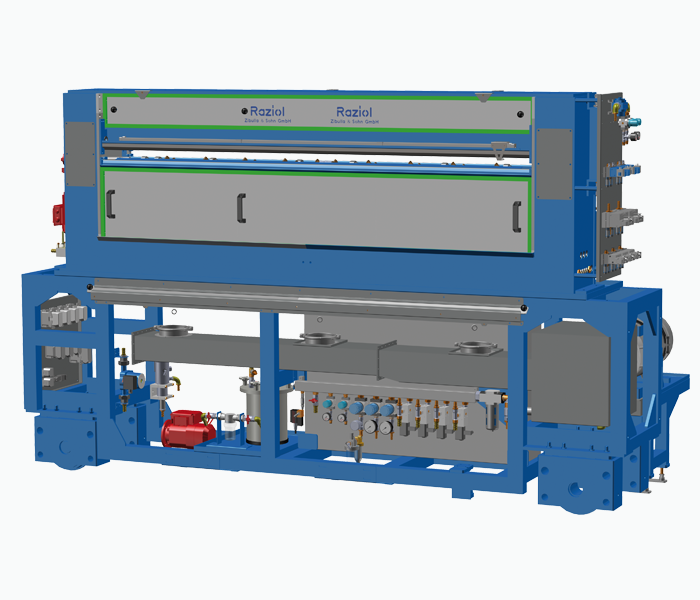

Premium SA-P spray system

High-performance lubrication system for partial lubrication of coils and blanks

Raziol high-performance spray systems are designed for use in sectoral or partial lubrication of coil and/or blank material with a width of up to 4500 mm. They are used for lubricating tasks within highly complex production lines in the automotive industry. High-performance spray systems are, depending on requirements, equipped with a blank transport system and light barrier for clear detection of the blank start (e.g. for shaped blanks). A very high level of reproducible precision is achieved in the application area and quantity, thanks to the BS 25 high-performance nozzles. Different application quantities in and transverse to the material throughfeed direction can be programmed in this respect.

Function/ Equipment:

- Monitoring, control and logging of application quantities (target/actual)

- Easy compilation of recipe files (incl. offline) and fully automatic setting of all required parameters

- Drip-free processing of outer components (example) through use of wiper units (example)

- Self-explanatory control

- Integrated control unit from Beckhoff / Siemens

- Equipped with help, maintenance and diagnostic tools

-

Application of various lubricants (low to high-viscosity oils, hotmelts, Drylub)

Blank lubricator system SA PBA B PP 1000 80-50 T2 M2 Hotmelt

The manually manoeuvrable blank lubricator system is suitable for one-sided or double-sided lubrication of blanks.

The system is designed for simultaneous or separate application of 2 forming media, without the possibility of media becoming mixed within the closed dosing system (2 separate medium circuits). Two spraying fixture systems from the Compact BS 25/SRV-15 series are installed in a collective chamber and can be pulled out from the chamber via a telescopic drawer. A belt system ensures transport of the blanks through the spray chamber. The blank lubricator system is suitable for the utilisation of dry lubricants (hotmelt) and features an integrated heater system.

Function/ Equipment:

- Monitoring, control and logging of application quantities (target/actual)

- Integrated heater system up to a maximum 80 °C - integrated safety system

- Self-explanatory control

- Integrated SPS 4000 control unit

- Suitable for the application of hotmelt

English (UK)

English (UK)  Français (France)

Français (France)  Deutsch

Deutsch  Español (España)

Español (España)  Polski (PL)

Polski (PL)  简体中文(中国)

简体中文(中国)