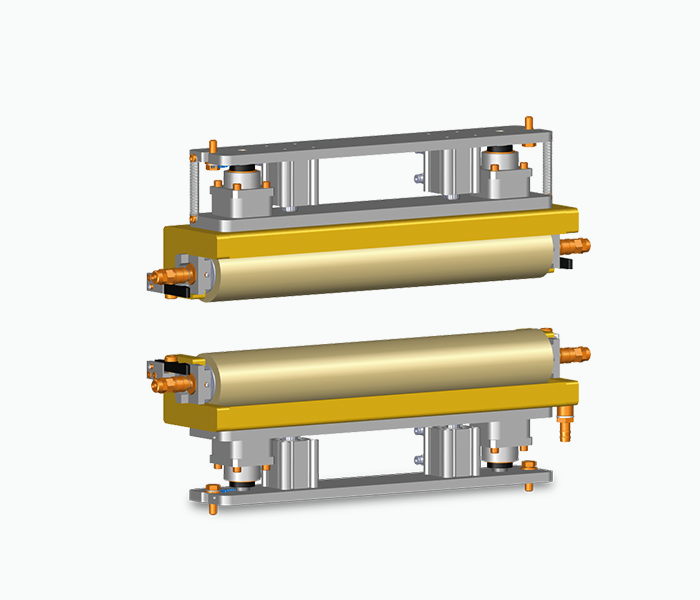

Roller lubricator with roller diameter 60 mm

The roller lubricator types RB F (B), RB FK (BK)-SW, RB F-SW, RB FK (BK)-P-SW, RB PF (PB)-SW and RB TF (TB)-P-SW may be equipped with optional felt, brush or Cellpor rollers which are supplied with lubricant internally.

They are used in the following metalworking processes: stamping, bending, deep drawing, rolling, profile rolling.

The lubricating rollers feature a diameter of 60 mm and are designed for forming processes with medium feed distances (up to 450 mm), moderate stroke rates (up to 200 strokes/min) and material thicknesses of up to 4 mm, and may be applied for a lubrication width of up to a max. 800 mm without any problems.

Surface contact of the lubricating rollers with the coil material prevents any generation of oil mist upon application of the forming lubricant during the feed process.

The surface contact between lubricating rollers and sheet metal surfaces can be effected as follows:

- Placement of top roller onto the material via springs

- Placement of top roller onto the material via pneumatic cylinders

- Placement of top and bottom roller onto the material via pneumatic cylinders

- Placement of top roller onto the material via adjusting spindle

Roller lubricator RB F

For the RB F introductory model, placement of the rollers is realised via tension springs. The tension springs press the rollers onto the coil material. Direct surface contact between the low-wear felt rollers and the coil material prevents the generation of oil mist during application of the forming lubricant.

RB F Variants and characteristics »PDF

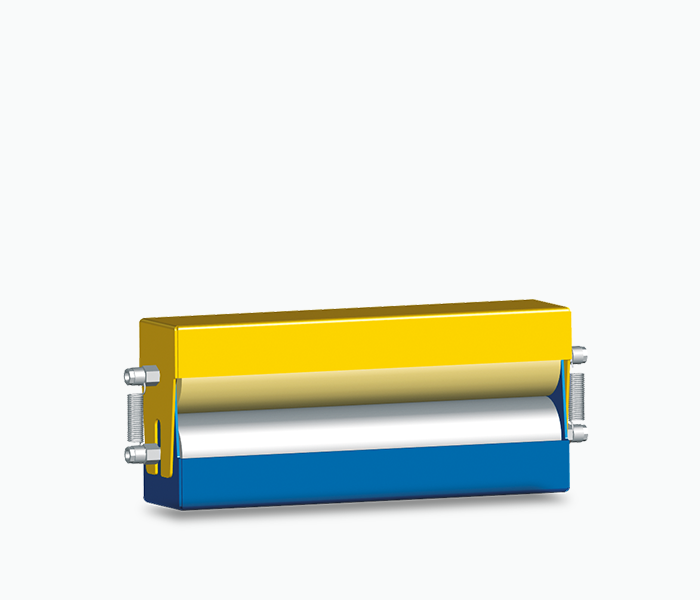

Roller lubricator RB B

Placement of lubricating rollers for the RB B roller lubricator onto the coil material is realised via two threaded spindles. Direct surface contact between the low-wear felt rollers and the coil material prevents the generation of oil mist during application of the forming lubricant.

RB B Variants and characteristics »PDF

Roller lubricator RB FK(BK)-SW

For RB FK-SW or RB BK-SW roller lubricators with quick-change configuration, placement of the rollers is realised via two tension springs. Roller lubricator types RB FK-SW / RB BK-SW feature an integrated tilting mechanism with an opening stroke of approx. 10 mm. This ensures improved loading for the beginning of the coil. Replacement of the lubricating rollers is performed without the use of tools.

RB FK-SW variants and characteristics »PDF

RB BK-SW variants and characteristice »PDF

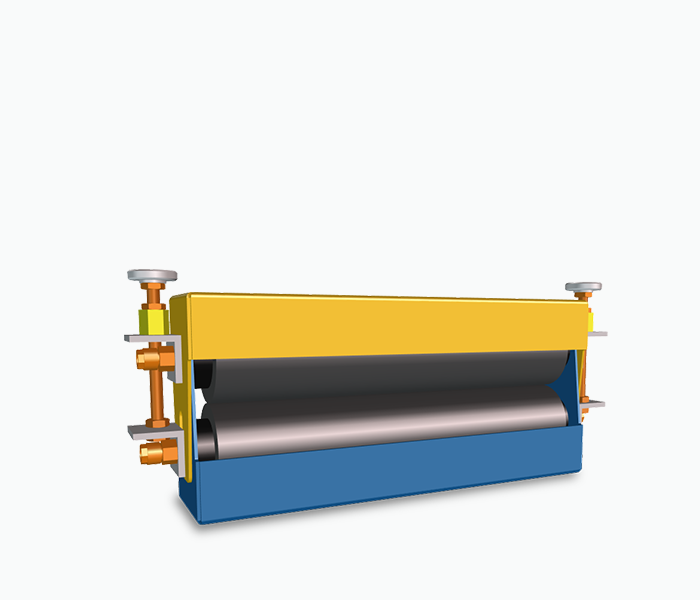

Roller lubricator RB F-SW

The roller replacement kits for the RB F-SW roller lubricator are fixed spring-loaded onto the guides in the housing. Direct surface contact between the coil material and the rollers is realised via two pneumatic cylinders. This guarantees an oil mist-free application of forming lubricants. Replacement of the rollers is performed without the use of tools.

RB F-SW variants and characteristics »PDF

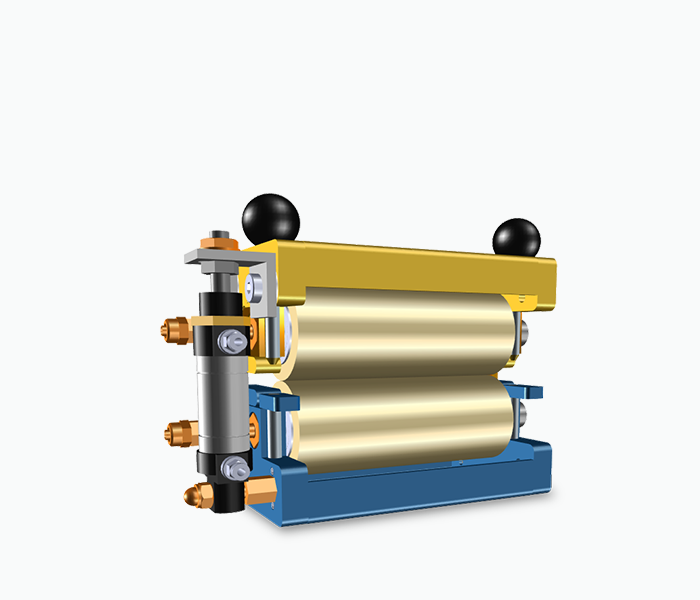

Roller lubricator RB FK-P-SW

The top roller for the RB FK (BK)-P-SW roller lubricator is pressed onto the coil material via a pneumatic cylinder featuring a stroke height of approx. 10 mm. Roller lubricator type RB FK(BK)-P-SW features an integrated tilting mechanism. This ensures optimum loading for the beginning of the coil. Replacement of the lubricating rollers is performed without the use of tools.

RB FK-P-SW variants and characteristics »PDF

Roller lubricator RB PF(PB)-SW

The top roller for the RB PF (PB)-SW roller lubricator is pressed onto the coil material by way of precision guidance elements and pneumatic cylinders featuring a stroke height of approx. 15 mm. Replacement of the lubricating rollers is performed without the use of tools.

RB PF-SW variants and characteristics »PDF

RB PB-SW variants and characteristics »PDF

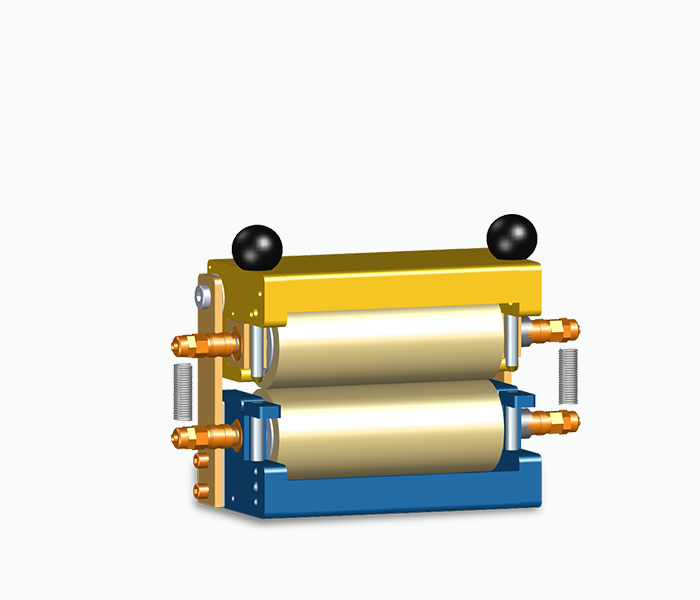

Roller lubricator RB TF(TB)-P-SW

The top and bottom roller for the RB TF-P-SW roller lubricator is pressed onto the coil material by way of precision guidance elements and pneumatic cylinders featuring a stroke height of approx. 25 mm.Replacement of the lubricating rollers (felt rollers or brush rollers) is performed without the use of tools.

RB TF-P-SW variants and characteristics »PDF

RB TB-P-SW variants and characteristics »PDF

English (UK)

English (UK)  Français (France)

Français (France)  Deutsch

Deutsch  Español (España)

Español (España)  Polski (PL)

Polski (PL)  简体中文(中国)

简体中文(中国)